Enhanced efficiency

Streamline vehicle assembly and maintenance with VR training to increase efficiency and precision while minimizing downtime.

Safety and compliance

Improve safety and ensure compliance with industry standards through immersive VR training.

Skill development

Accelerate the acquisition of automotive technical skills and product expertise through VR training.

Enhanced efficiency

The automotive industry is effectively leveraging VR to boost assembly efficiency, refine maintenance practices, and enhance overall operational performance.

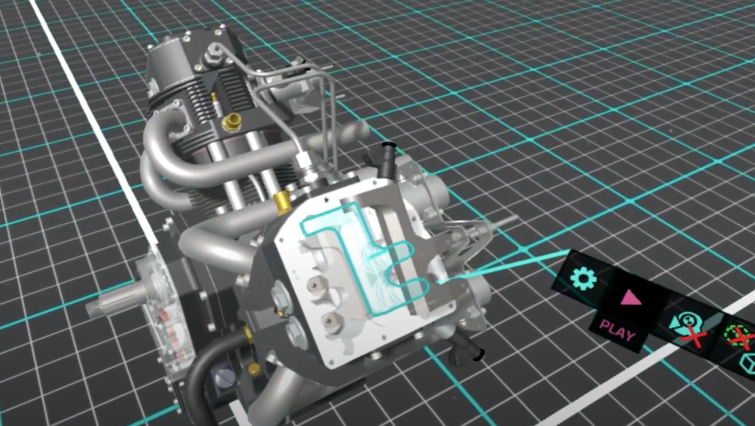

Assembly line training in VR immerses employees in a virtual automotive production environment, where they practice complex assembly tasks such as engine installation and dashboard configuration without the risk of real-world errors.

Maintenance and repair simulations provide hands-on experience with virtual replicas of automotive parts, improving technician proficiency in tasks like transmission diagnostics and electrical repairs. This direct interaction ensures higher precision and safety in actual operations.

Process optimization through VR helps identify and rectify production bottlenecks, while quality control scenarios allow staff to practice spotting and fixing defects, ensuring vehicles meet high quality standards.

Recruitment and onboarding benefit from immersive VR experiences that introduce new hires to the automotive assembly line, enhancing their understanding of production dynamics before stepping onto the factory floor.

Equipment maintenance training in VR teaches critical maintenance procedures, reducing machinery downtime and extending lifespan, while supply chain simulations enhance logistical efficiency and decision-making across production networks.

Safety and compliance

VR safety training provides automotive workers with the opportunity to navigate potentially hazardous scenarios such as chemical spills and equipment malfunctions in a risk-free virtual setting.

This training encompasses key areas like emergency response procedures, handling automotive-specific hazardous substances, and strict adherence to industry safety protocols.

Each session is conducted within a controlled VR environment, allowing employees to practice and master safety measures crucial to the automotive industry.

Skill development

VR is transforming skill development in the automotive industry by offering immersive, hands-on training for a wide array of technical tasks.

Technicians and engineers benefit from VR experiences that simulate complex systems like engine diagnostics, electrical troubleshooting, and transmission repairs.

This virtual training environment allows for intensive practice without the risks associated with real-world training, significantly shortening the learning curve and enhancing overall technical proficiency.

VR training is key for staff to master both existing and new vehicle models, enhancing their understanding of advanced features. It boosts the effectiveness of sales teams, who use VR to demonstrate vehicle benefits more clearly, increasing customer satisfaction and sales outcomes.

New to VR training?

Tap into the expertise of the world´s biggest companies and learn

the 5 considerations to get it right from the start.

Explore the Immerse solutions

Platform

An easy way to manage, scale and report on immersive training

The Immerse Platform

Off-the-shelf content

130+ licensable VR apps for a variety of enterprise use cases

VR marketplace

Custom content

Expert design and development services

used by the world’s biggest companies