In this customer story

Increasing production capacity

Accelerating medicines to market

Increasing operator time-to-competency

Reducing machinery downtime

Standardising training quality

Reducing product waste

Reducing costs

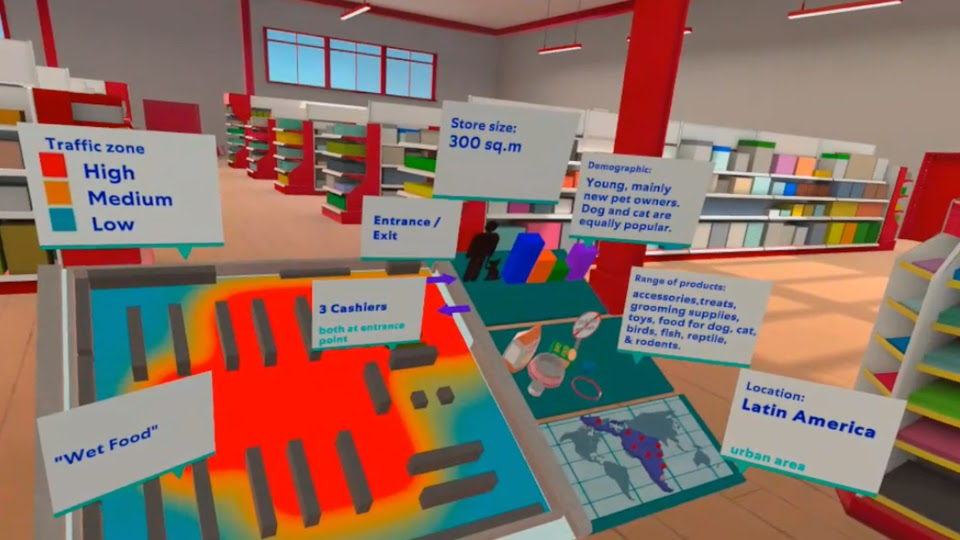

This global top 10 pharmaceutical company sought to enhance operational efficiency in one of its crucial manufacturing processes by virtualizing training. Previously, the training of operators was constrained by Good Manufacturing Practices (GxP) which prohibited trainees from training on live production lines. Instead, they relied on the costly practice of building duplicate production lines, video tutorials, and a classic slide-based approach. This was further impacted by the availability of trainers, with training quality variable across sites.

The company’s objective was to minimise manufacturing downtime, expedite the skill acquisition of operators, standardise training quality, and diminish product waste during the training phase. To achieve this, the company ventured into virtual reality (VR), utilising a combination of Immerse content and distribution solutions.

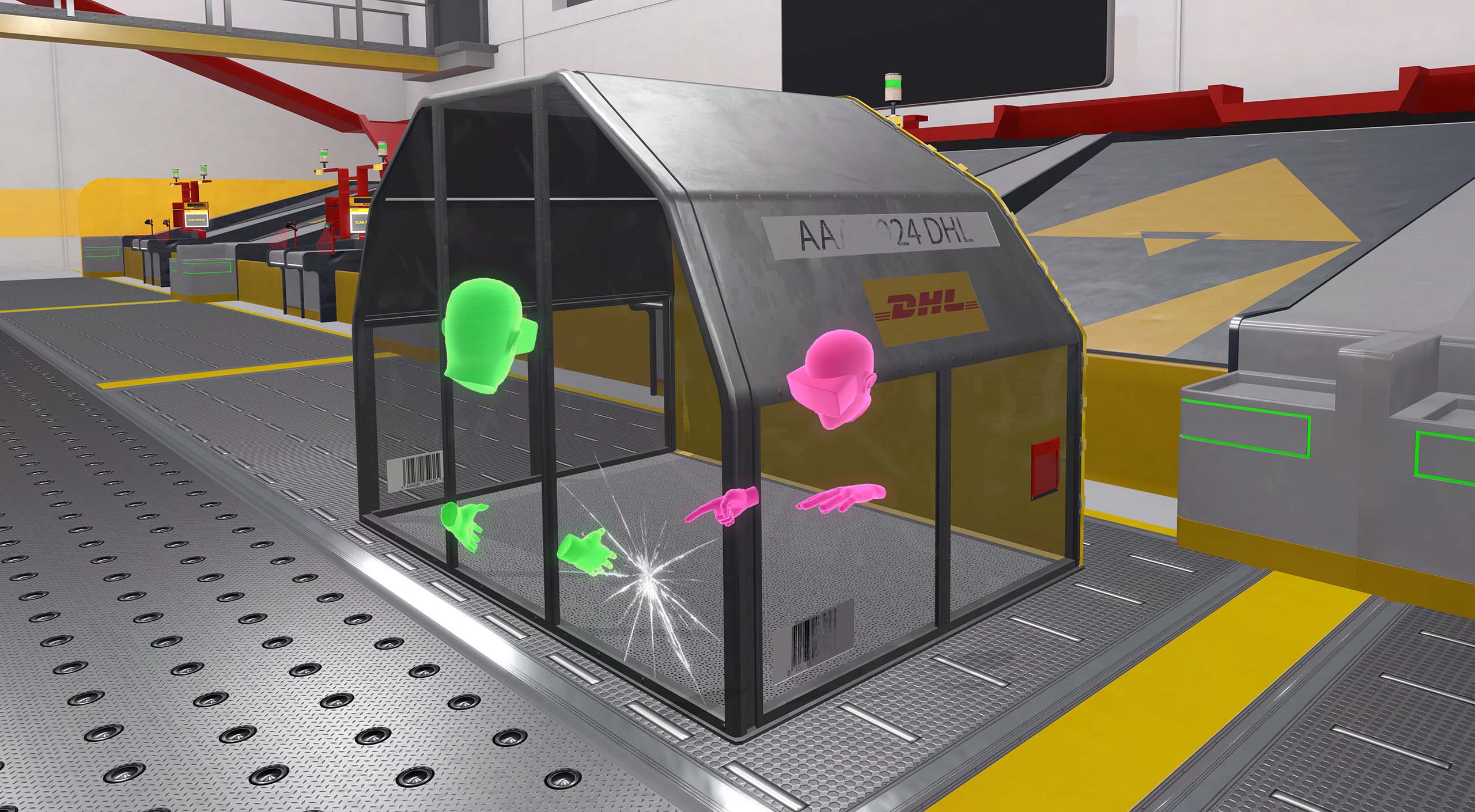

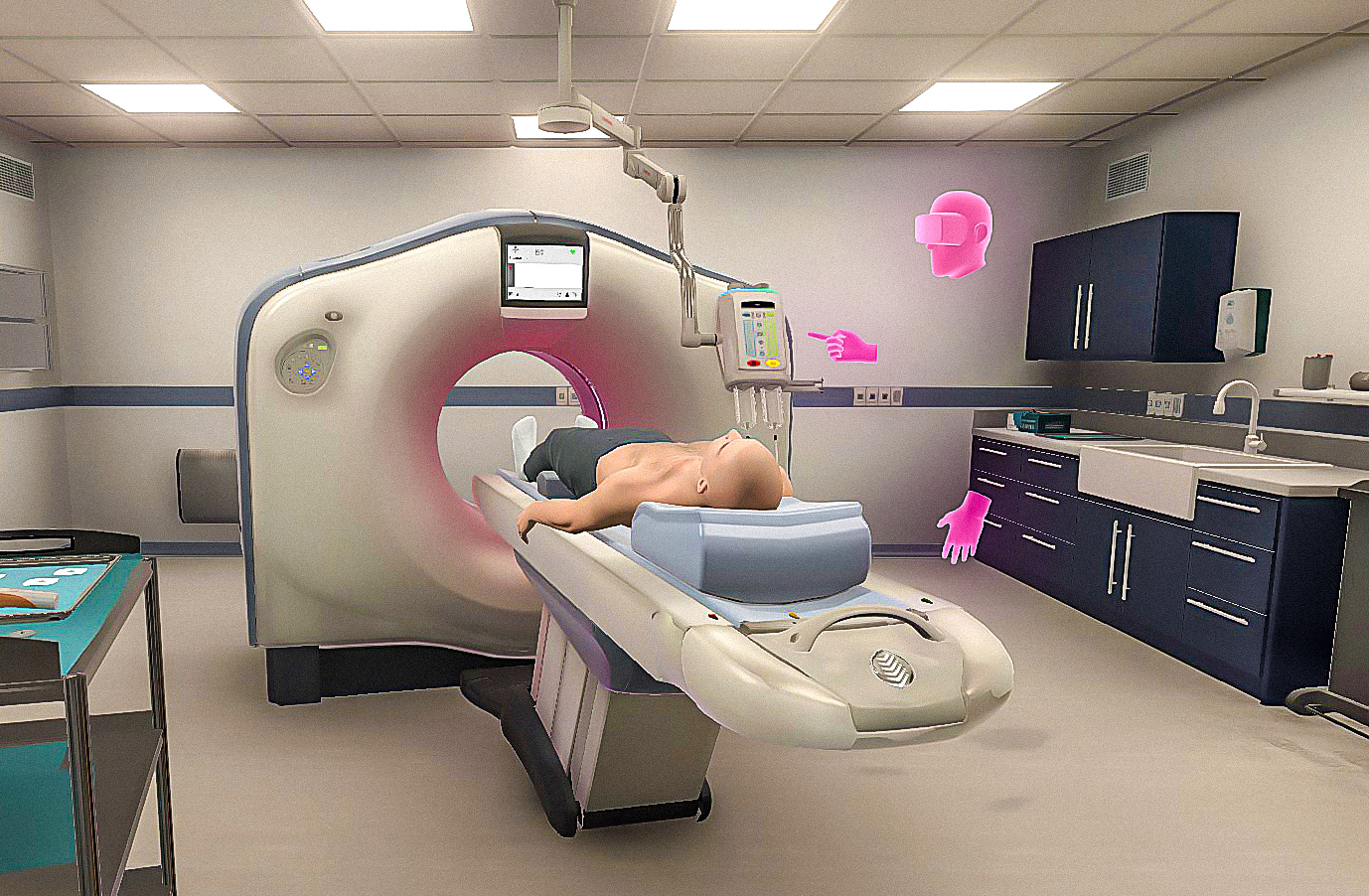

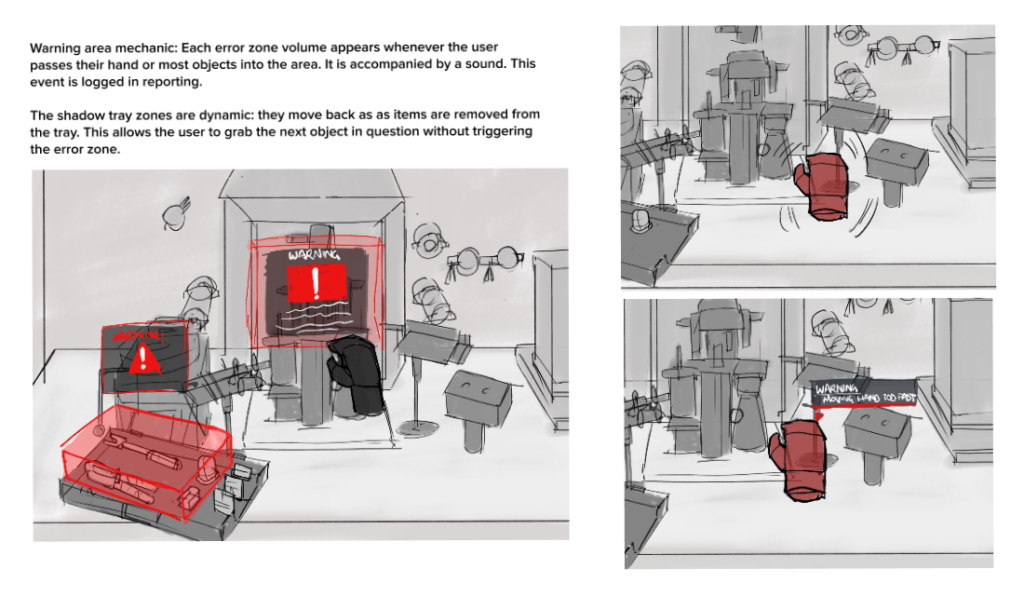

Immerse developed an intricately detailed VR training simulation, replicating the specific manufacturing equipment and environment inside the Reduced Access Barrier System (RABS) to mimic scenarios such as cross-contamination, for example moving your hands too fast. This allowed employees to practice a complex, 250-step aseptic manufacturing process in a safe, virtual setting, eliminating the need for physical equipment access. Immerse solutions further facilitated easy deployment and tracking of training progress.

The training led to a 50% reduction in training duration and a 52% increase in the speed at which operators reached competency.

The training, enhanced by its immersive and interactive nature, significantly improved the efficiency and effectiveness of the learning process. The voice-over which named parts as they trained allowed trainees to rapidly familiarise themselves with the equipment much to the surprise of established colleagues. The realistic nature of the experience (mimicking the RABS environment) meant that trainees were building muscle memory all the time, ready for the real world.

This led to a remarkable 50% reduction in training duration and a 52% increase in the speed at which operators reached competency. Trainee feedback was exceptionally favorable.

Additionally, the VR training allowed operators to practice extensively in a virtual setting before handling actual equipment, which reduced machinery downtime cost and product waste.

And finally, the training established a quality standard that could be replicated across sites.

Results

- Reduction in product waste, more medicines going to patients

- 50% reduction in the time required for training

- Operators achieved competency 52% faster

- A notable £6.75 million revenue generation through reduced downtime

- In VR, trainees could train 4 times in 1 hour, vs attending a 1 hour classroom session

- Trainers had more time for other training activities and learnt new skills

- Sustainability & cost benefits, as a-septic gowns aren’t required in VR

- Immerse enabled objective and auditable data capture, enhancing training assessment and feedback mechanisms